Earth stood hard as iron, water like a stone;

Snow had fallen, snow on snow, snow on snow,

In the bleak midwinter, long ago.

- Christina Rossetti

As the days grow short and cold, and memories of warm afternoons sailing fade in the distance…here’s some tips on setting up your Martin 242 for winter storage!

1. One of the most important things specific to the Martin242 is taking care of the aft cockpit drain tubes. The “interestingly designed” geometry of these features means that water will pool down in the elbow when the boat is not in the water, which can cause the tubes to crack in freezing conditions. There’s various advanced solutions to this problem involving a lot of glass work to replace the existing tubes, but a much simpler one is to stick some rags in the aft drain tubes to drain water via capillary action.

2. Strip all the ropes off the deck so they don’t get moldy – mainsheet, pole downhaul, vang, cunningham, and traveler are relatively easy. Furling line is a bit trickier because you’ll have to re-wind the furling barrel if you unspool it, you could consider just coiling the end and hanging it off the pulpit to make your life easier.

3. Attach tracer lines to halyards with bowline knots so all the halyards can get sent up the mast and not bang all winter or get as moldy. Also protects them from UV (if the sun ever does come out).

4. Take your sails home to stay dry all winter. For those with living arrangements involving restricted square footage due to astronomical property values in BC, I find under the kitchen table works well. Partners don’t complain too much when you explain the thrill of winning the first race of the season because your sails stayed nice and dry. Life jackets, random hats and gloves kicking around the bilge, expensive GPS instruments – get those off the boat too.

5. If your yacht club or marina allows you to plug in somewhere – a heater and even dehumidifier if possible inside the cabin is great to keep the boat nice and dry inside. Even a low-draw marine fan to keep some air moving is a good option if you don’t want to burn too much power.

6. Take any old gasoline you have lying around in jerry cans & dispose properly. In Vancouver some of the return-it depots will take old gas (in a proper container) and give you a credit to purchase a new jerry can.

7. Run the outboard engine until the fuel line and carburetor are mostly dry (I actually try to do this every time I use the engine so the little bit of fuel doesn’t leak inside the boat). Better if you can take the outboard right off the boat and store it somewhere nice and warm and dry for the winter.

8. Drain the engine carb if possible by loosening off the carb drain screw so the gas doesn't turn to gel and then harden over the winter and gum up the carb: big $ to get it cleaned out professionally (see picture for example, although every engine is probably slightly different).

image credit to practical boat owner

9. Make sure the boat is properly seated on the trailer.

10. Check for leaks during the winter and seal them in the spring or on dry days.

One other option (this is what we do on Back in Black) is to take the mast down, rest it over the pushput & pulpit, and tarp the whole thing.

Our boat has some nagging leaks in a few spots, and there is usually some water that runs down the mast no matter how well you try to seal this up – so this option usually keeps the boat nice and dry. Taking the mast up and down is pretty fast if you use the Fleet 1 gin poles. The other advantage of this method is that you should likely be dropping the mast at least once a year to inspect it and do some maintenance anyways:

- clean it with acetone and rags (shroud wires get coated with gunk all year long, so cleaning the wires once a year with acetone is a good idea so it lessens the streak marks on mainsails)

- check all shackles and swaged ends

- re-tape where required to prevent spinnaker tears

- replace halyards as needed

- check the windex and mast whip

- check the spreader bracket for cracks and if it doesn’t have a bar welded across its front (see item 4 in this bad boy) this is a great time to call on Sandy, the mobile welder (See Buy & Sell page for contact info)

On November 28th, the 13th boat of 2020 changed hands (11th in the Pacific Northwest Region): Jenn Potter and Gordon Tulip of Royal Victoria Yacht Club sold Dark Horse, #157, to Hawk Attew, 14, and family, who will sail it out of Cowichan Bay - exploring the nearby islands with the family and racing.

Hawk worked long hours over the past two summers with tremendous energy and focus with the goal of saving enough to buy his first 242. He plans to build on the sailing skills he developed while learning to sail in Lake Ontario as a pre-teen. Hawk’s dad, Jason, previously raced on a 242 back in the late 90’s and looks forward to his son gaining the same experience he did. They plan on racing Dark Horse in next year's NA's at Nanaimo. This is excellent news, as it continues a recent string of inactive or semi-active boats getting sold or chartered to keen new owners.

With a dark blue hull, Dark Horse has an excellent NA's race record, coming 3rd overall in 2019, 2nd overall in 2007, and 3rd overall in 1993. The boat was listed for CDN$8,000 and was previously refurbished by Jason Rhodes and Matt Kirk-Buss in 2007 to an NA’s race-ready standard, with epoxy barrier coat and bottom paint.

It came with:

3 mains: Regatta (Sobstad - 2017, Club Racing Sobstad - 2009, Cruising - 2007)

3 jibs: most recent is a 2015

3 spinnakers: most recent was a crispy 2015

a completed Measurement Certificate

It did not come with a trailer or yard dolly.

Welcome to the Regional Fleet, Hawk and enjoy your first 242! (The photo below shows Hawk standing beside Dark Horse on the 28th.)

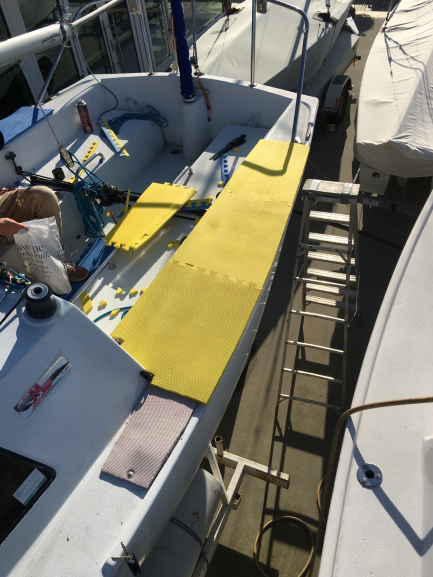

The Pacific Northwest Regional Measurers (Ken Holland, Chris White, Ken Machtley, Jeremy Smith, Anthony Collett, Allan Strain, Tim Murphy, Jim Hyslop, Frank Rogers, and Michael Clements) proposed to allow M242 owners to experiment with deck padding in 2021 onwards with these goals in mind:

- To make the M242 more comfortable to race by eliminating the deck rail “bump” issue

- To attract new owners and crew who will like the increased comfort.

Other owners may come up with even more innovative solutions that are simpler, possibly cheaper, and more or equally effective: let the experimentation begin.

On November 25, the IMCA Technical Committee met via Zoom and agreed that:

- The deck padding concept had merit

- It did not affect the boat structurally

- It did not enhance performance

- It did provide a higher degree of comfort for skipper and crew

- It was inexpensive

- Other solutions may be developed. For example, Mike George (MG Marine) suggested that he would contact someone in his area and see about a foam solution. Another idea proposed by Ken Machtley prior to the meeting was to use button snaps for snapping cushions onto the cockpit seating: one monolithic custom molded cushion on each side with 4-6 snaps for attachment.

- The Technical Committee will allow all owners & crew to conduct unrestricted experiments with deck padding in 2021 in order to develop the best solution(s) for the greater good (400-500+ minds on the issue are better than just a few)

- The IMCA Technical Committee will revisit this topic at the end of 2021 and determine if some Class Standards can be developed with regard to color and design

- If more time is required by the Technical Committee to evaluate the solution set(s) then it may decide to roll the decision process into 2022.

- $85 for 12 Interlock foam mats (they come in packs of 4 at Home Depot, Model # is 20009, SKU is 100811661)

- $10 for 5 feet of ¾’ width double-sided sticky Velcro (available on Amazon)

- Some duct tape

- $18 for a can of 3M Super 77 spray-on glue

- 2 long screws and washers

Page 27 of 52